Hot end: Pan

The Pan inspection system is mounted on the carousel / forming machine(s) and measures the outer dimensions of the shoulder, neck and lip while the product is mounted in a chuck. Pan systems are available for indexing and non-indexing forming machines.

The hot-end design requires a dedicated optical design. Electronics, camera, lens and lighting unit are placed outside the carousel, on the back end of the Pan system. The full unit can be moved backward and forwards using guiding rails on the side of the unit. This allows faster maintenance; slide the unit back, perform the required activity and slide the unit in place again.

As a safety measure, a break part has been designed (inside the carousel). In case of bad positioning of the unit by an operator, the break part will be torn off and thus prevents damage to the unit and other expensive parts. The break part is cheap and easily replaceable.

Inspection-results are displayed on the screen in a graphical form (each measurement in a graph). In addition to that, the performance of each individual chuck and tool can be reviewed, as well as the performance over the full batch for each measurement.

Download Pan leaflet

Before oven: Telesto – vial inner diameter inspection

Before oven: Telesto – vial inner diameter inspection

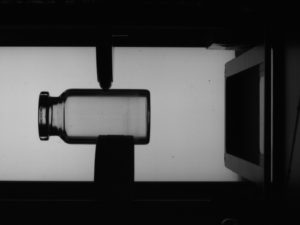

Telesto is designed to measure the inner diameter of the vial using a perpendicular view. The vial is lifted from the line and aligned with the optical configuration. A full scan is performed in the measured inner diameter.

The Telesto system can be combined with other inspection systems, keeping the same user interface. Telesto uses special handling and a dedicated optical configuration to provide very accurate inspection performance.

Download Telesto leaflet

Before oven: Thyone – dimensional vial inspection

Thyone is designed to inspect the outer dimensions of the vial. The Rotowheel takes the vial out of the line and present it in front of the cameras. A rotation wheel rotates the vial, while multiple images are taken. After inspection, the Rotowheel places the vial back into the line and a trigger signal to the reject unit is send, when the parameters are not met. Measurements such as total length, lip and neck diameter etc. can be performed.

Download Thyone leaflet

Before oven: Pandora – concavity and thickness inspection

Pandora is designed to inspect the bottom thickness and bottom concavity of a vial. The system consists of an optical probe mounted on a linear slide, aligned perpendicular to the bottom of the vial. When the line has stopped indexing, the linear drive moves the optical probe across the bottom of the vial. During this movement, inspection is being performed.

Download Pandora leaflet

After oven: Rhea – Cosmetic and dimensional inspection of vials

VIMEC Rhea systems perform cosmetic inspection on vials, a final inspection which is typically performed shortly before the packing. The Rhea system uses different viewing angles and various camera types to perform cosmetic inspection on various parts of the product. Given the large number of possible defects, the design anticipates on a setup of multiple complimentary Rhea systems to ensure complete cosmetic inspection without compromising quality.

The system has been optimized to allow the best coverage of the product without any concession in speed or performance. The main areas for inspection include body, neck, lip, sealing area (top) and bottom. Rhea uses bright field illumination for all viewing angles and the vial is rotated over 360⁰.

Download Rhea leaflet

After oven: Atlas – Stress in Glass Inspection

Atlas systems performs inline stress detection after the Oven. It is designed to detect the presence of residual stress in the body or neck of a vial.